Perfect Milling – with 3 to 5 Axes

Milling is a machining process used to create workpieces with specific geometric shapes. Like all machining methods, it involves removing material from a raw part in the form of chips. Milling falls under the category of machining with geometrically defined cutting edges, as the geometry of the cutting edges on milling tools is known.

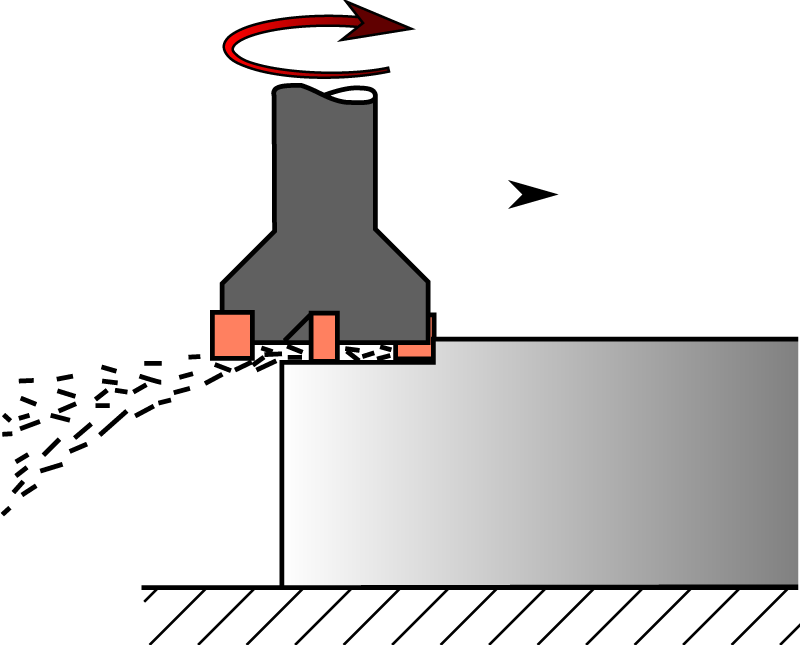

During milling, material is removed as the milling tool rotates at high speed around its own axis. This is achieved by either moving the tool along the desired contour or moving the workpiece accordingly. The feed movement in milling occurs either perpendicular or at an angle to the rotational axis of the tool. In contrast, drilling involves a feed movement along the rotational axis, while turning involves rotating the workpieces around their own axis while the tool follows the contour.

Precision and Accuracy in Milling

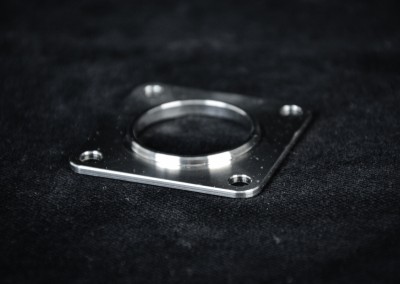

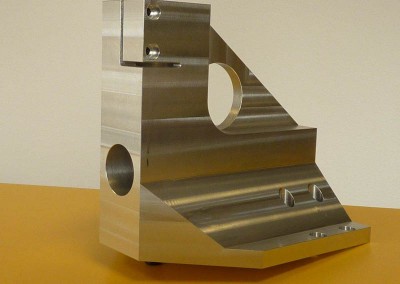

Milling is particularly used for creating flat surfaces, including grooves or guides for moving machine parts. However, modern milling machines can also generate complex three-dimensional shapes such as turbine blades or dies.

Milling exhibits some distinct characteristics compared to other machining processes. During milling, the individual cutting edges do not have continuous contact with the workpiece. They enter the material during a rotation, removing chips, and then disengage from the workpiece. This characteristic is referred to as interrupted cutting in the technical literature. This results in an intermittent, fluctuating cutting force acting on the tool.

The chip thickness changes during rotation and is not constant as in most processes. However, while the cutting edges are not in contact with the workpiece, they can cool down, preventing excessive heating. Additionally, the interrupted cutting generates short comma-shaped chips that cannot become entangled in the machine. Separate measures for chip breaking are therefore not necessary.

Our Milling Capabilities

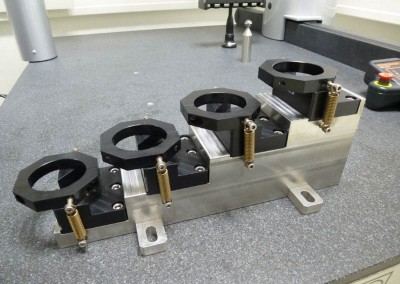

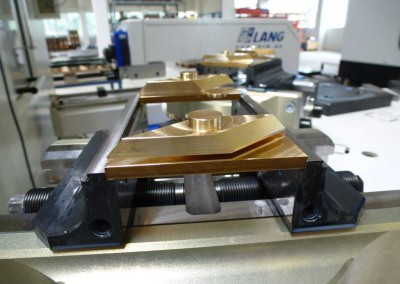

With our extensive range of machines, we offer our customers versatile and highly flexible solutions:

- Processing of all materials Up to 800x800x1800mm machining range

- 3-, 4-, and 5-axis machining Plates, cutouts, as well as blanks (castings and forgings)

- Translation of 3D CAD data into CNC code using Esprit CAM

- Production of small, medium, and large series

- Quality standard according to ISO 9001:2015

- Customized inspection processes according to your preferences

We look forward to your inquiry!

According to your specifications, we manufacture highly precise CNC turning and milling parts. We provide consultation to ensure your products are manufactured in a way that is both technically and economically advantageous. This way, we become part of your solution and align ourselves with your products - WE ARE PART OF IT!